Process & Automated equipment

-

-

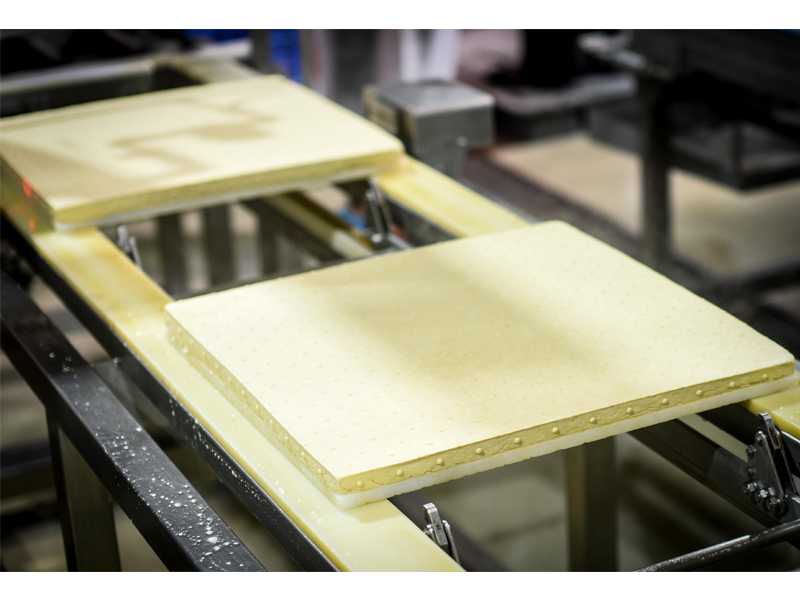

Automatic Tofu Machinery

(The raw soybeans are made into tofu cubes)

Soaked soybeans → ground into soymilk → add gypsum (food grade) (make it solidify) → break flowers (leak the excess water) → make tofu (press molding) → cut into pieces → salted tofu block (make it achieve natural anti-corrosion) → rinse the tofu block (wash away excess salt) → dry sterilization → completed.

-

-

The Ferment for Brewing Area

( It is an important step to make fermented bean curd delicious)

Steam soybeans and rice → connected to self-developed, self-made and purified strains → control temperature and humidity in the best range in order to make fermentation → proper mixing → bean paste (bean meal) is completed.

-

-

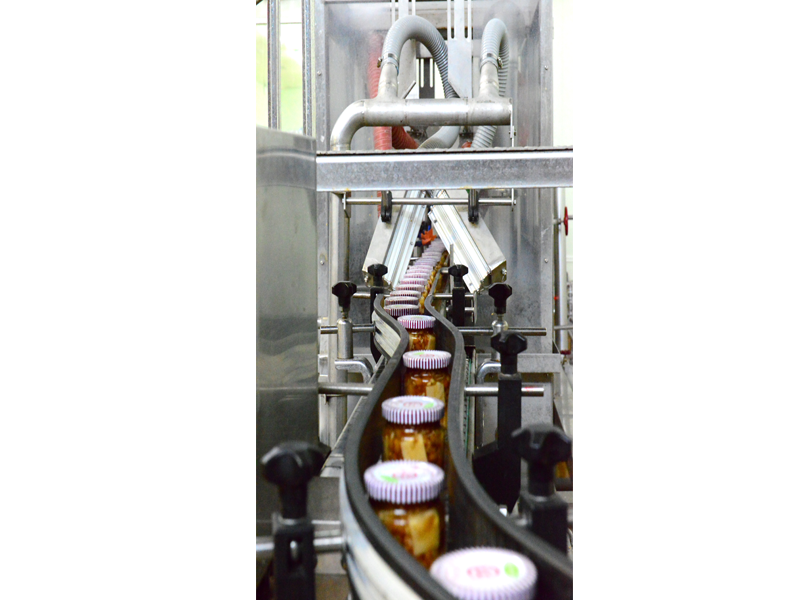

The Filling area

(fill the tofu block + bean paste (bean paste) into bottles)

Manually place the tofu block in the first layer of the bottle → machine filling the bean paste → placing the second layer of the tofu block → filling the bean paste with the machine → repeat the above procedure until the product is full (depending on the size of the bottle, determine the number of tofu blocks).

-

-

The Ripening Room

(Place the filled bean curd in the ripening room to ferment it)

The ripening room adopts the constant temperature and humidity control. The fermented bean curd will ferment in the ripening room for about 30~60 days. It depends on the degree of fermentation. When it is fully cooked, it will be capped and packaged.

-

-

The Gold Detector (Metal Detector)

(The matured fermented bean curd is subjected to a metal test to detect metal or foreign matter).

-

-

Automatic Packaging Machinery

(Wrap the fermented bean curd which passes the Metal Detector)

Cover → bottle cleaning → cover film → date of produce → labeling → photo detection (cover film, date, label) → packaging into boxes.

(Automatic packaging machine can pack 8,000 boxes of fermented bean curd a day, reducing manpower and greatly increasing efficiency.)